Quality Control

Bridesburg Foundry employs strict quality control processes and seasoned engineers.

We are compliant with multiple quality standards, including ISO-based systems, Mil-I-45208A and we may maintain ASNT qualified personnel and procedures. We will ensure that every step of our work is well planned and reviewed for quality assurance. Scroll down to access our list of Safety Data Sheets.

Process

There is no substitute for time-tested experience when it comes to producing metal castings for your special applications. Bridesburg’s comprehensive manufacturing processes include a full No-Bake Molding System, Squeezer, Roto-lift, Roll-over, Pin Lift molding stations, Diversified core capabilities, and Solid-state electric induction melting.

Capabilities

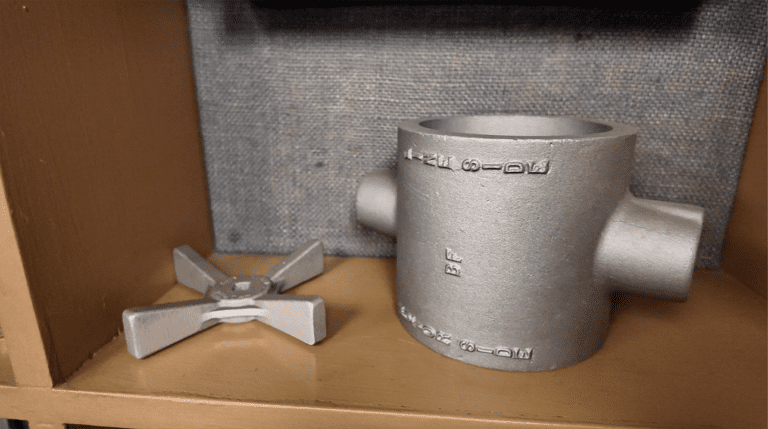

Bridesburg produces non-ferrous pressure type, specialty, and engineering alloy castings. Many stages are involved in the manufacturing of every casting produced. Throughout these stages, several factors remain constant: strictly enforced quality control, skilled workmanship, and feedback to keep our customers informed about job progress.

Facility

At Bridesburg, our most valued asset is our human resource. Only through the skill, experience, and dedication of our people can we make the most of our advanced facilities. A complete cleaning and finishing department is maintained to OSHA standards. A pattern shop and machine shop are on site for the convenience and service of our casting customers.

Technology

We’re proud of our reputation for quality, reliability, and personal commitment to meeting our customers’ standards and schedules. We’re particularly proud of our employees, whose knowledge and skills have meshed with new technology and modern processes for a unique blend of diversified capabilities.

Products

Bridesburg produces non-ferrous pressure type, specialty, and engineering alloy castings. We produce a broad spectrum of casting designs, sizes, weights, and alloys for a variety of applications and markets. Major industries include valve and pump, electronics, fire protection, navy and marine, ordnance, petrochemical, power generation, and many others.